Additional menu

CGI Capabilities

- Precision Machining

- Advanced Products

- Vertically Integrated Services

- Materials List

- Multi-tasking machines (multiple spindle, multiple turret)

- CNC Gear Fabrication

- Swiss Type Multi-tasking Machines

- CNC Lathe Machining

- CNC Vertical Milling

- CNC Horizontal Milling with Multi-Pallet Robot

- CNC 5-Axis Milling

- CNC Swiss Type Turning

- Wire EDM

- CNC Cylindrical Grind

- Hone

- Precision Gear Fabrication

- Gear Hobbing

- Gear Shaping

- Bevel Gear Cutting

- Internal Gear Broaching

- Laser Welding

- Heat Treating

- Passivation

- Specialty Process Sourcing Expertise

- All required fixturing is designed and manufactured in house

- Highly Qualified Inspection Department

- Zeiss Contura Coordinate Measuring Machine (CMM)

- Brown and Sharp Coordinate Measuring Machine (CMM)

- PECo Next Dimension 300 Gear Analyzer

- Micro Vu Vertex Vision System

- Multiple Starrett Optical Comparators with Digital Readout

- TESA Scanner

- PECo Dual Flank Test Roll Checker

- Micro Check Dual Flank Test Roll Checkers

- Multiple Vari-Roll Dual Flank Test Roll Checkers

- Mitatoyo Toolmakers Microscope with Digital Readout

- Inspection Xpert software for First Article Reports

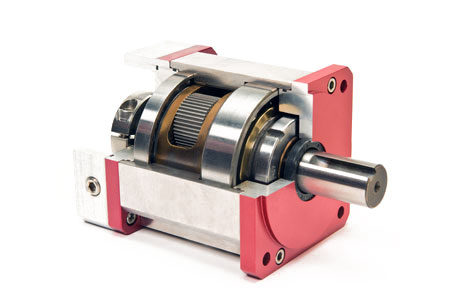

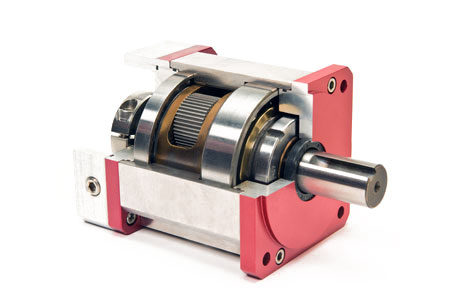

- Custom Gearboxes

- Fabricated to Customer Design or Designed by CGI Engineers to Customer Requirements

- In House Manufacture of Precision Individual Components

- Assembly and testing to Customers Requirements

- Complex Machined Components

- Assembly and Testing of Mechanical or Electro-Mechanical Assemblies

- ESD Procedures and ESD Compliant Workbenches

- Assembly and Testing of Small to Large Multi-items component lists

- Testing of a variety of functions based on Customer Requirements

- Inventory Management Solutions including Kanban and Blanket Purchase Order

Design Engineering Services Utilizing Latest Software and Technology:

- SolidWorks

- SolidWorks Simulation (Finite Element Analysis)

- Gear Design and Analysis Software

Applications Engineering specializing in:

- Individual Gear Design

- Gear Train / Gear Box Analysis

- Customized Gear Box Design

- Precision Machined Component Design

- Design Support for Advanced Devices and Systems

Testing/Validation Services:

- Process Flowchart

- Process Failure Modes Effects and Analysis (pFMEA)

- Special Process Validations

- First Article Reports

- Process Capability Studies

- Collaborative Inspection Plan Development

- Control Plans

Sourcing Services integrated into CGI’s robust Quality System:

- Specialty Processes

- Off shore sourcing

Training Services:

- Gear Seminars for Engineering Teams

- Small or Large Groups

- Located at CGI’s Headquarters or Your Site

- Training Webinars

Other Services:

- Manufacturing Engineering Support

- Design for Manufacturability

- Fixturing Design and Fabrication

- Prototyping Support (Solid Model, 3D Printer)

- Process controls designed and implemented

- Process development for Assembly and Testing of Motion Control Assemblies for Advanced Devices and Systems

- Minitab Statistical Analysis tools

- Computer Aided Machining (CAM)

- Six Sigma black belt expertise

- Failure Analysis Services

- Rapid Prototype and 3D Printer Services

- Infor Visual Enterprise ERP system allows for integrated manufacturing system along with systematic, traceable and controlled processes .

- Kanban/Inventory Management programs

CGI regularly works on a large variety of materials. Below is a partial list of materials we work with. If a particular material is not on this list, please enquire.

Stainless Steels (all)

- 300 Series all types

- 400 Series all types

Aluminum (all types)

Exotics Metal Materials

- Titanium

- Nitronic all types

- Inconel

- Stellite

- M-50

- BG42

- Tungsten

- Waspaloy

- Hasteloy

- Cobalt

Ceramics

Exotic Plastics (all types)

- PEEK

- PTFE

- Nylon

- Acetals

- Polycarbonates

- Ultems

- Polyurethane

- Rubber

- Polyimide / amide

Precision Machining

- Multi-tasking machines (multiple spindle, multiple turret)

- CNC Gear Fabrication

- Swiss Type Multi-tasking Machines

- CNC Lathe Machining

- CNC Vertical Milling

- CNC Horizontal Milling with Multi-Pallet Robot

- CNC 5-Axis Milling

- CNC Swiss Type Turning

- Wire EDM

- CNC Cylindrical Grind

- Hone

- Precision Gear Fabrication

- Gear Hobbing

- Gear Shaping

- Bevel Gear Cutting

- Internal Gear Broaching

- Laser Welding

- Heat Treating

- Passivation

- Specialty Process Sourcing Expertise

- All required fixturing is designed and manufactured in house

- Highly Qualified Inspection Department

- Zeiss Contura Coordinate Measuring Machine (CMM)

- Brown and Sharp Coordinate Measuring Machine (CMM)

- PECo Next Dimension 300 Gear Analyzer

- Micro Vu Vertex Vision System

- Multiple Starrett Optical Comparators with Digital Readout

- TESA Scanner

- PECo Dual Flank Test Roll Checker

- Micro Check Dual Flank Test Roll Checkers

- Multiple Vari-Roll Dual Flank Test Roll Checkers

- Mitatoyo Toolmakers Microscope with Digital Readout

- Inspection Xpert software for First Article Reports

Advanced Products

- Custom Gearboxes

- Fabricated to Customer Design or Designed by CGI Engineers to Customer Requirements

- In House Manufacture of Precision Individual Components

- Assembly and testing to Customers Requirements

- Complex Machined Components

- Assembly and Testing of Mechanical or Electro-Mechanical Assemblies

- ESD Procedures and ESD Compliant Workbenches

- Assembly and Testing of Small to Large Multi-items component lists

- Testing of a variety of functions based on Customer Requirements

- Inventory Management Solutions including Kanban and Blanket Purchase Order

Vertically Integrated Services

Design Engineering Services Utilizing Latest Software and Technology:

- SolidWorks

- SolidWorks Simulation (Finite Element Analysis)

- Gear Design and Analysis Software

Applications Engineering specializing in:

- Individual Gear Design

- Gear Train / Gear Box Analysis

- Customized Gear Box Design

- Precision Machined Component Design

- Design Support for Advanced Devices and Systems

Testing/Validation Services:

- Process Flowchart

- Process Failure Modes Effects and Analysis (pFMEA)

- Special Process Validations

- First Article Reports

- Process Capability Studies

- Collaborative Inspection Plan Development

- Control Plans

Sourcing Services integrated into CGI’s robust Quality System:

- Specialty Processes

- Off shore sourcing

Training Services:

- Gear Seminars for Engineering Teams

- Small or Large Groups

- Located at CGI’s Headquarters or Your Site

- Training Webinars

Other Services:

- Manufacturing Engineering Support

- Design for Manufacturability

- Fixturing Design and Fabrication

- Prototyping Support (Solid Model, 3D Printer)

- Process controls designed and implemented

- Process development for Assembly and Testing of Motion Control Assemblies for Advanced Devices and Systems

- Minitab Statistical Analysis tools

- Computer Aided Machining (CAM)

- Six Sigma black belt expertise

- Failure Analysis Services

- Rapid Prototype and 3D Printer Services

- Infor Visual Enterprise ERP system allows for integrated manufacturing system along with systematic, traceable and controlled processes .

- Kanban/Inventory Management programs

Materials List

CGI regularly works on a large variety of materials. Below is a partial list of materials we work with. If a particular material is not on this list, please enquire.

Stainless Steels (all)

- 300 Series all types

- 400 Series all types

Aluminum (all types)

Exotics Metal Materials

- Titanium

- Nitronic all types

- Inconel

- Stellite

- M-50

- BG42

- Tungsten

- Waspaloy

- Hasteloy

- Cobalt

Ceramics

Exotic Plastics (all types)

- PEEK

- PTFE

- Nylon

- Acetals

- Polycarbonates

- Ultems

- Polyurethane

- Rubber

- Polyimide / amide